Crucible melting furnaces (PT)

Our company produces crucible furnaces (PT) for melting of non-ferrous metals and their alloys with a melting point up to 1100°C.

In the design of furnaces we use gas and liquid-fuel burners from the company Weishaupt (Germany), and crucibles from JSC "Luga Abrasive Plant" or "POLYTEG" (Germany), at the choice of the Customer.

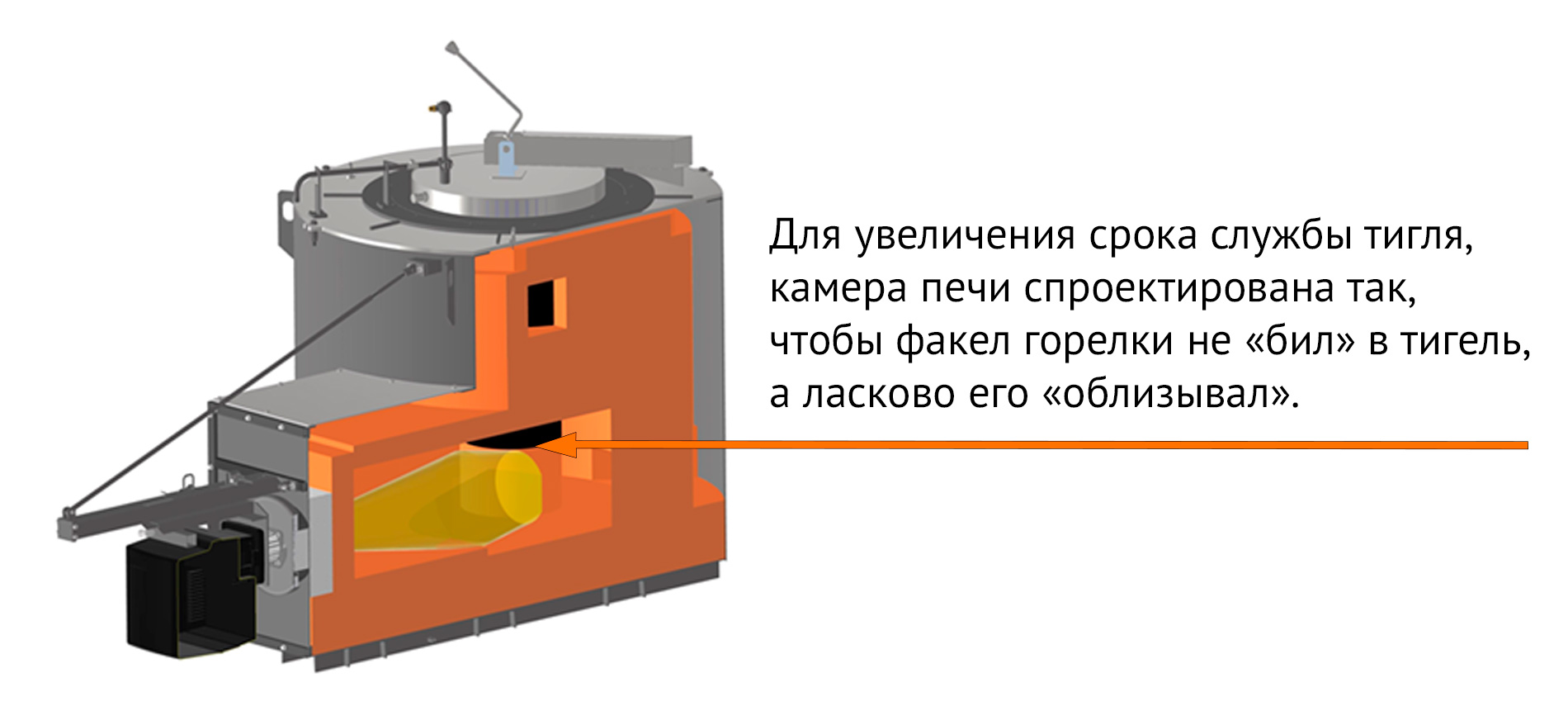

The lining of the furnace is multi-layered, combined. The working chamber in the standard version is made with a ША-5 firebricks.

The furnace control system has 2 modes: melting and exposure. In the melting mode, the burner operates at the capacity required for rapid melting of the metal, and in the "exposure" mode operates at the capacity sufficient to maintain the melt temperature.

The temperature in the furnace is controlled by 2 thermocouples.

The basic configuration of the PT furnace includes:

- furnace body with refractories and lid;

- burner;

- crucible;

- clamps for crucible installation in lined casing;

- control cabinet;

- immersion calibration thermocouple;

- flue gas thermocouple;

- operational documentation;

- copy of TR CU declaration.

Our furnaces are certified for use in hazardous production facilities.

For more information, please call +7 (917) 295 77 77, or ask us a question on the website.

To receive technical and commercial proposal, please download and fill in the questionnaire and send it to us by e-mail: info@optim-toledo.com

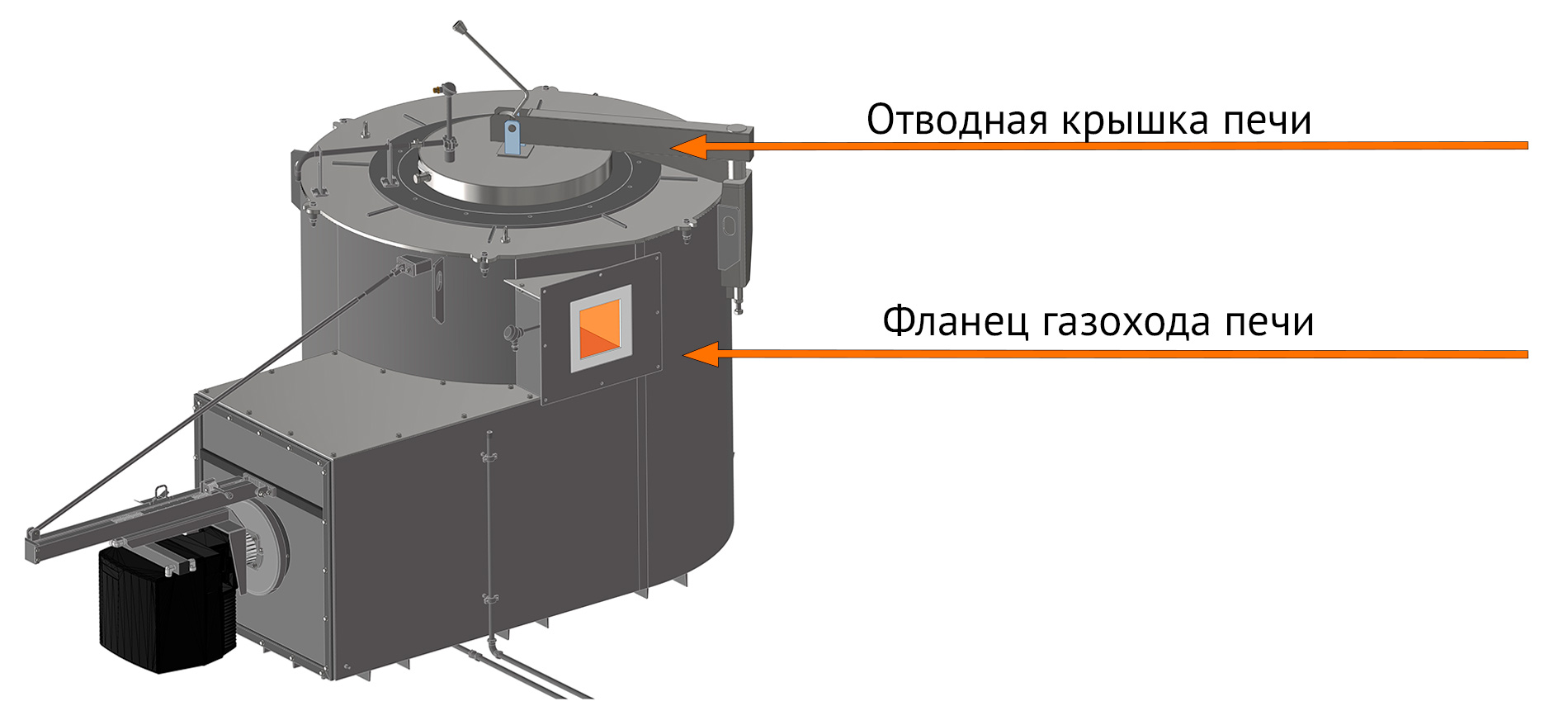

General view of furnace

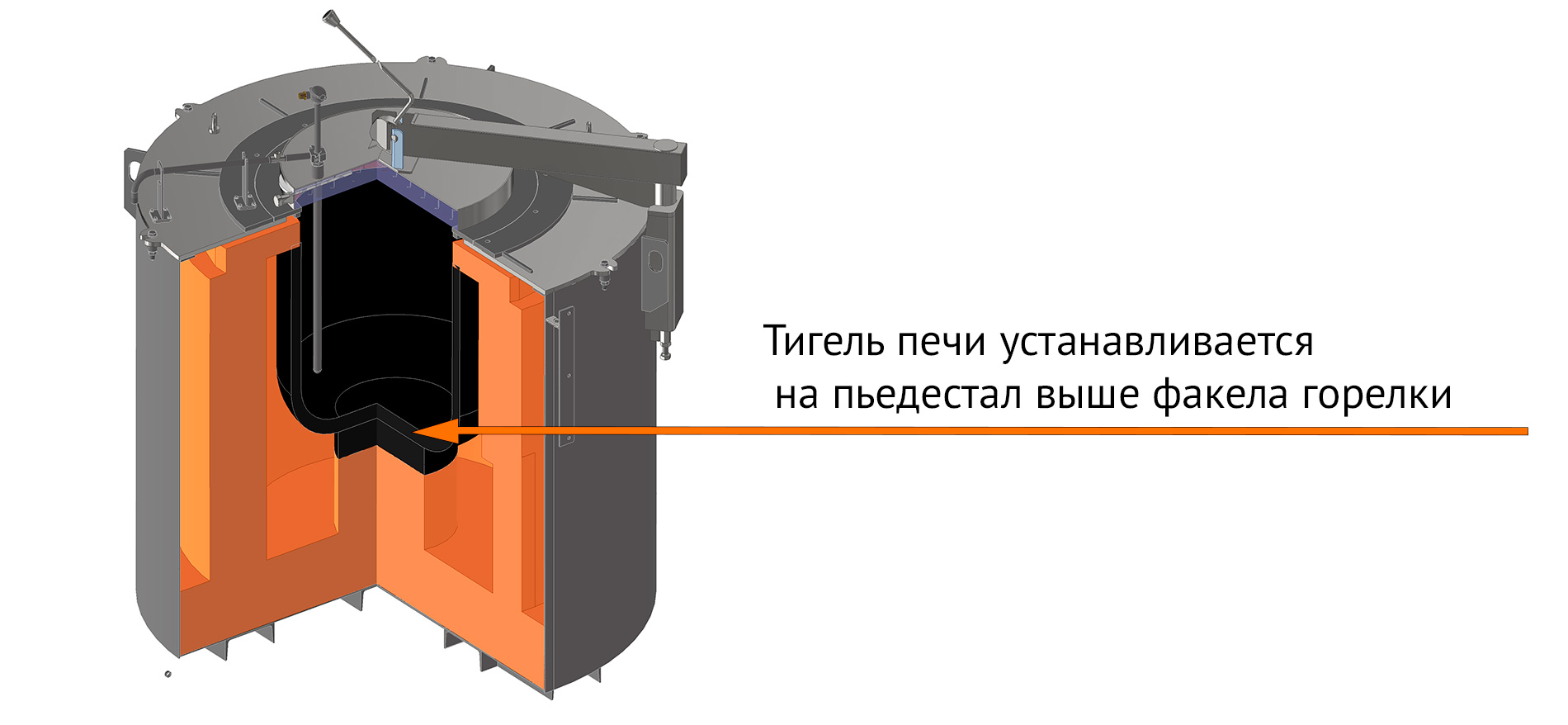

Cross-sectional view of furnace chamber

Technical characteristics of crucible melting furnaces

| Model | Nominal capacity of the furnace by melt (kg) | Burner power range | max. gas consumption/hour (cubic m) |

| Aluminum | |||

| ПТ-0,04 | 47 | 50 | 6 |

| ПТ-0,06 | 70 | 50 | 6 |

| ПТ-0,1 | 90 | 110 | 13 |

| ПТ-0,16 | 140 | 110 | 13 |

| ПТ-0,25 | 230 | 200 | 24 |

| ПТ-0,45 | 440 | 200/350 | 24/42 |

| ПТ-0,5 | 540 | 350 | 42 |

| ПТ-0,75 | 650 | 350/550 | 42/66 |

| Copper | |||

| ПТ-0,1 | 120 | 110 | 13 |

| ПТ-0,16 | 144 | 110 | 13 |

| ПТ-0,25 | 240 | 200 | 24 |

| ПТ-0,45 | 420 | 350 | 42 |

| ПТ-0,5 | 480 | 350 | 42 |

| ПТ-0,75 | 700 | 550 | 66 |

| ПТ-1 | 950 | 550 | 66 |